The Fristam FM is a multi-stage, high pressure centrifugal pump that features high, non-pulsating flow for quality product and less maintenance. FM pumps have become the benchmark for reverse osmosis system pumps with a non-pulsating flow and lower maintenance costs. Additionally, the FM’s seal and bearing life are usually measured in years rather than months.

The multi-stage centrifugals have been developed specifically to generate high pressures and operate under extreme pressure conditions. Capable of withstanding up to 1,000 PSI inlet pressure and available with up to four stages, the Fristam FM Series can be configured to meet your pressure and flow needs.

FM pumps are built with a heavy-duty bearing block assembly, mounted on a stainless steel base, complete with a coupling guard. The bearing block uses labyrinth oil seals and heavy-duty bearings. A close-coupled version (CCFM) is available for applications with space constraints.

The mechanical shaft seal is selected carefully to be suitable for the particular application. Both the rotating and stationary part materials and the corresponding elastomers used are thoroughly checked for compliance with all the specifications and standards required.

Perfect for reverse osmosis and similar high pressure applications, this series is less costly to purchase and maintain than other types of high pressure pumps. Fristam’s high pressure centrifugals provide a steady non-pulsating flow which improves product quality and extends run time with less maintenance.

Fristam FM pumps are designed without any dead zones and are, of course, entirely suitable for CIP/SIP.

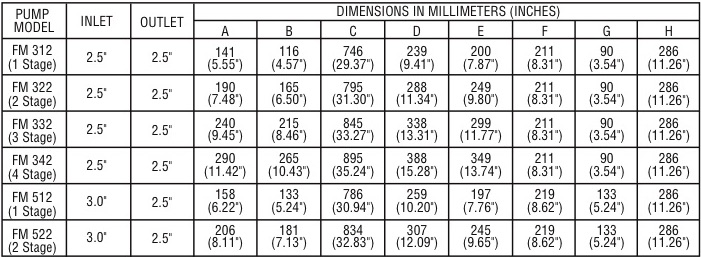

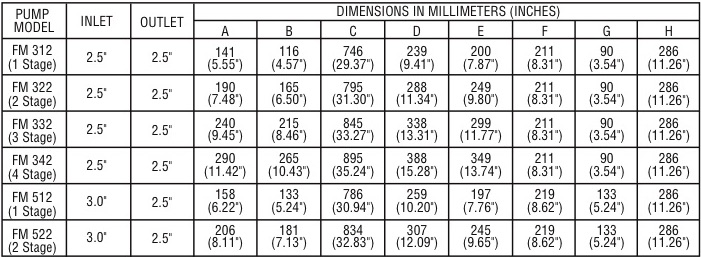

TECHNICAL DETAILS CHART