FKL Positive Displacement Pump

The Fristam FKL - Most Durable and Reliable PD Pump

Stop rebuilding, repairing, replacing, and spending your valuable time on other PD pumps, Fristam’s FKL pump simply runs better and lasts longer. The FKL’s shaft and unique balanced rotor is designed to reduce rotor-to-housing contact that can prematurely wear your pump. In fact, the shaft is engineered for lasting performance; its large diameter is stronger than others and is guaranteed for life never to break.

Do you have an existing PD pump that you’d like to replace but are concerned about the ports not lining up with the Fristam? Do not worry, The FKL’s port-to-port dimensions can be customized for easy replacement for other PD pumps, so make the change without worrying about making those costly piping changes

The FKL is the most durable and reliable sanitary positive displacement pump available. It is rated for up to 500 PSI standard.

Large Diameter Shaft

- Up to 25% larger diameter

- Solid 316L Stainless Steel

- Reduces rotor-to-housing contact

- Guaranteed for life never to break!

Balanced Rotors

- Distributes force evenly

- Handles higher pressures

- Doesn’t bend into housing

Heavy Duty Gearbox – The Business End

The Gearbox may be the most important part of a pump when it comes to long life and uninterrupted performance.

- Large double tapered bearings for longer bearing life

- Low maintenance oil lubrication lasts 8-times longer than grease

- Bearing-supported gears for even load distribution

True CIP – No Disassembly Required

The FKL is the first close-clearance PD pump to be designed for “True CIP” (Clean-In-Place). A proper CIP System allows the pump to operate during cleaning.

NO ROTOR REMOVAL:

Fristam’s FKL needs nothing removed from the pump for CIP. The cover remains in place. This provides a simple and effective solution with minimal downtime.

REDUCES COSTLY DOWNTIME - NO PUMP DAMAGE – PROVIDES SAFETY FOR EMPLOYEE’S:

Eliminating rotor removal and installation reduces costly downtime and eliminates the chance of damaging the pump, or worse yet, injuring employee’s.

NO PREFORMANCE LOSS:

Other manufacturers have retrofitted their designs to accommodate CIP by increasing the internal slip path. This “shortcut” significantly reduces efficiency. The FKL cleans in place without losing any performance.

DESIGNED FOR EASY MAINTENANCE

The round exterior on the FKL pump provides for a sleek look and maximum cleanability. An ultra-clean stainless steel gearbox is optional for difficult environments.

Seamless Changeover:

FKL seals are completely contained within a cartridge. They can be pre-assembled and shelved for easy, one piece replacement.

Additionally, no housing or pump modifications is needed to change the Fristam FKL from a single seal to a double seal or from an O’Ring seal to a mechanical seal.

Offset Rotor Bolts:

Traditional rotor nuts can back-off when pump pumping viscous products. Once loose, they can severely damage pumps. The FKL is equipped with offset rotor bolts that lessen the unwinding force of the product.

As it rotates eccentrically, the bolt provides natural agitation to promote cleanibility in the cavity.

Extended Housing Studs:

To protect against housing-to-shaft contact and accidental seal damage, Fristam provides long housing studs to guide the housing past the shaft during assembly and disassembly.

APPLICATIONS:

Dairy, Meat, & Food

DAIRY AND CHEESE

The dairy industry has long been the staple of Fristam Pumps’ user base. Fristam knows dairy. From gentle cream transfer to pumping frozen butter, the FKL can handle almost anything. The large-capacity FKL 580 is becoming the ‘Curd Pump’ of choice in dairies. Its gentle transfer capability allows the FKL to maintain product integrity, increases fat content and reduces fines for better curd yield.

- Milk & cream

- Yogurt & sour cream

- Cheese curd & whey

- Butter

- Cream cheese

- Processed cheese

- Sweetened condensed milk

MEAT AND POULTRY

Large rectangular inlets and front cover discharges are available to keep meat products, such as MDM, moving. Heavy-duty construction allows the FKL to withstand differential pressures up to 500 psi and adapt to variable product throughput requirements.

A stainless steel gearbox option is provided for difficult environments.

- Slurry

- Ground Poultry

- Whole & liquid egg

- Salted egg yolk

- Meat emulsion

- Blood plasma

FOOD & BAKING

Options for Kolsterising® and tungsten carbide coating, along with alloys Hastelloy® and AL-6XN®, make the FKL more resistant to internal wear.

The FKL is a favorite for abrasive products, including chocolate and fruit puree. In fact, Fristam has developed a special jacketed single seal and rotor clearances for chocolate processors.

De-gassing covers are available to allow the FKL to pump dough and products with entrained air.

- Chocolate & peanut butter

- Tomato sauce & paste

- Condiments & dressings

- Dough, batter & sponge

- Fruits, fillings, & frostings

- Soup & stew

- Masa paste

- Starch slurry

Beverage & Industrial

BEVERAGE AND BREWING

The FKL accommodates high pressures for syrups and other viscous products. Its close clearances reduce slip on thin products, increasing efficiency. Also, the FKL has excellent suction capabilities.

- Soft drink syrup

- Juice concentrate

- Beer & wort

- Yeast

- Corn syrup

- Coffee extract

- Malt extract

INDUSTRIAL

The FKL can also fulfill the needs for processing beyond food and beverage. Its close clearances allow the FKL to pump thinner industrial liquids, and the variety of alloys can handle abrasive or caustic products.

- Biodiesel

- Solvent

- Glue

- Paint

- Dye

- Glycerine

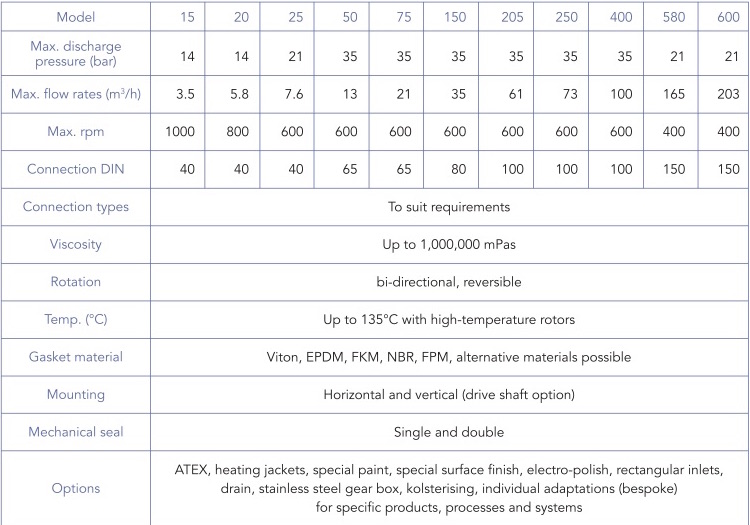

TECHNICAL DETAILS CHART