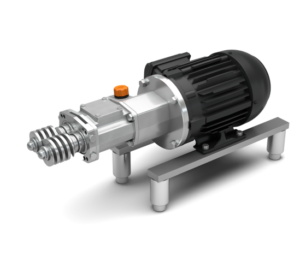

The FDS Nano utilizes a twin-screw mechanism to generate a continuous, controlled fluid flow. Within a cylindrical housing, two intermeshing screws rotate in unison, efficiently drawing liquid from the inlet and delivering it at a uniform rate. This design significantly reduces turbulence and shear, making it ideal for processing sensitive or shear-sensitive materials.

Designed for ultra-smooth, pulse-free flow, the FDS Nano ensures accuracy with virtually no pulsation. The FDS can also handle up to 70% air without air-locking, maintaining consistent operation and protecting product quality throughout your process.

With speeds up to 4,000 RPM, it streamlines your process, cuts capital and maintenance costs, and reduces contamination risk by eliminating the need to switch equipment between steps.

With six screw sizes and a range of customizable options, the FDS Nano can be engineered to meet your exact needs. Precision-machined components ensure contact-free operation for minimal wear, while easy-access seals, external screw alignment, and vibration-reducing couplings keep service simple and downtime low.